Revolutionize On-Site Processing: The Expanding Prospects of Portable Trommel Screens

The portable trommel screen is transforming material processing by bringing unmatched on-site flexibility. Its core advantage is rapid deployment – contractors and operators can move the unit directly to the material source, eliminating costly trucking of raw feed to distant fixed plants. This makes it ideal for remote job sites, smaller-scale projects, disaster debris cleanup, and temporary processing needs. Whether screening topsoil, processing C&D waste on a demolition site, or scalping aggregates for a rural road project, the portable trommel screen delivers essential classification where it's needed most, significantly boosting operational agility and opening new market opportunities for mobile service providers.

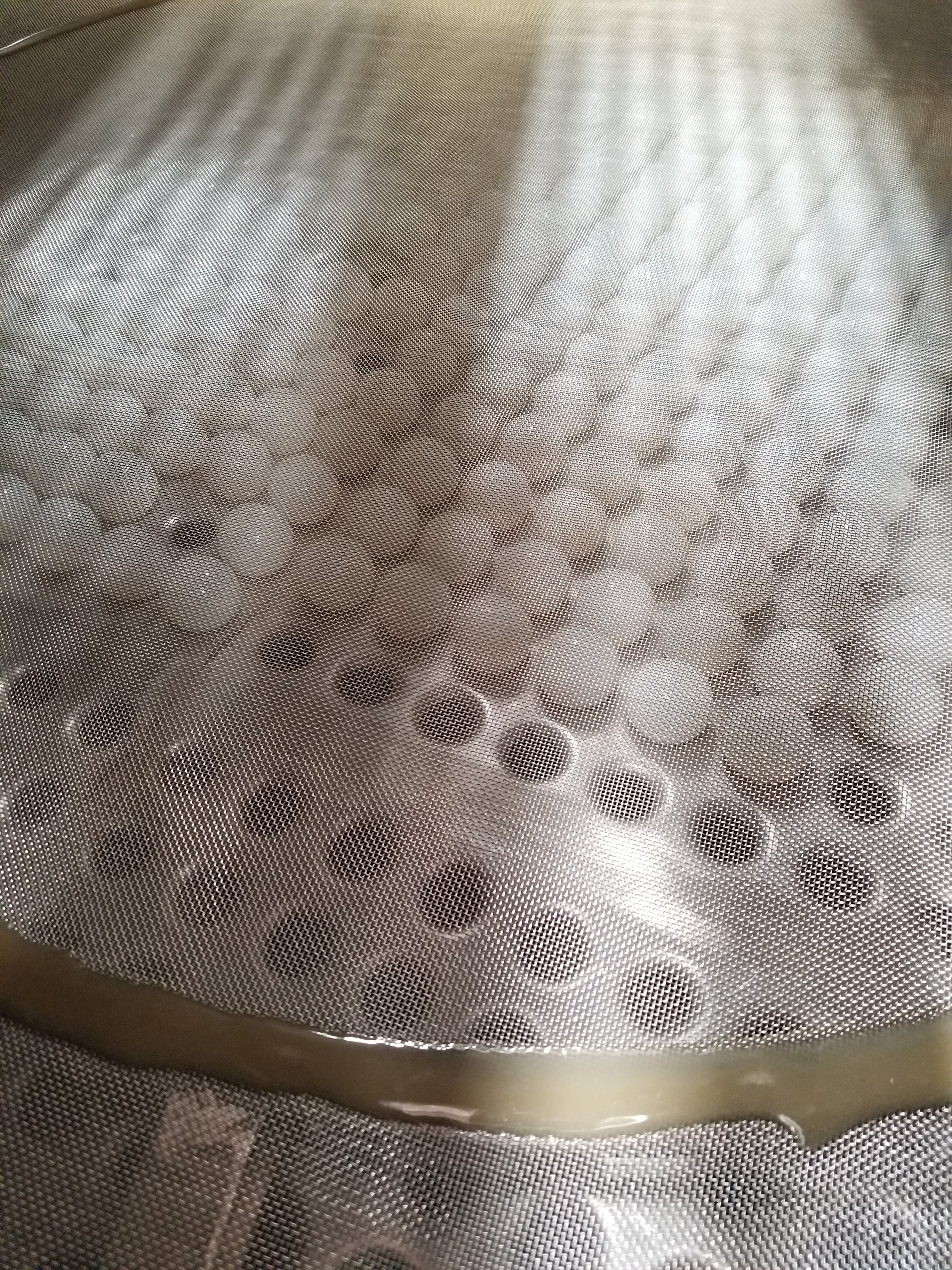

Beyond mobility, the portable trommel screen offers compelling cost efficiency and environmental benefits. By processing materials directly at the source, it drastically reduces hauling costs, fuel consumption, and associated carbon emissions. Furthermore, it enables on-site resource recovery, allowing contractors to separate valuable aggregates from demolition debris or clean fill from contaminated soil for immediate reuse or sale, bypassing landfill fees and generating revenue. The ability to quickly set up and process diverse materials – from compost and wood chips to sand, gravel, and recycled concrete – makes the portable trommel screen a versatile, profit-generating asset that minimizes waste and maximizes resource utilization.

The application prospects for portable trommel screens are rapidly expanding across diverse sectors. Landscapers and soil producers use them for on-demand screening of topsoil and compost at client locations. Demolition and environmental remediation contractors rely on them for immediate debris sorting and contaminated soil processing. Aggregate producers deploy them for small-batch screening or remote pit operations. Mining exploration teams utilize them for initial site assessment and bulk sampling. Even event management sees potential for post-event waste sorting. With continuous advancements in trailer design, power options (including hybrid/electric), and screening efficiency, the portable trommel screen is poised to become an indispensable tool for any operation valuing speed, versatility, and sustainable on-site processing.