WhatsApp / Phone: +86-13839082305

E-mail: [email protected]

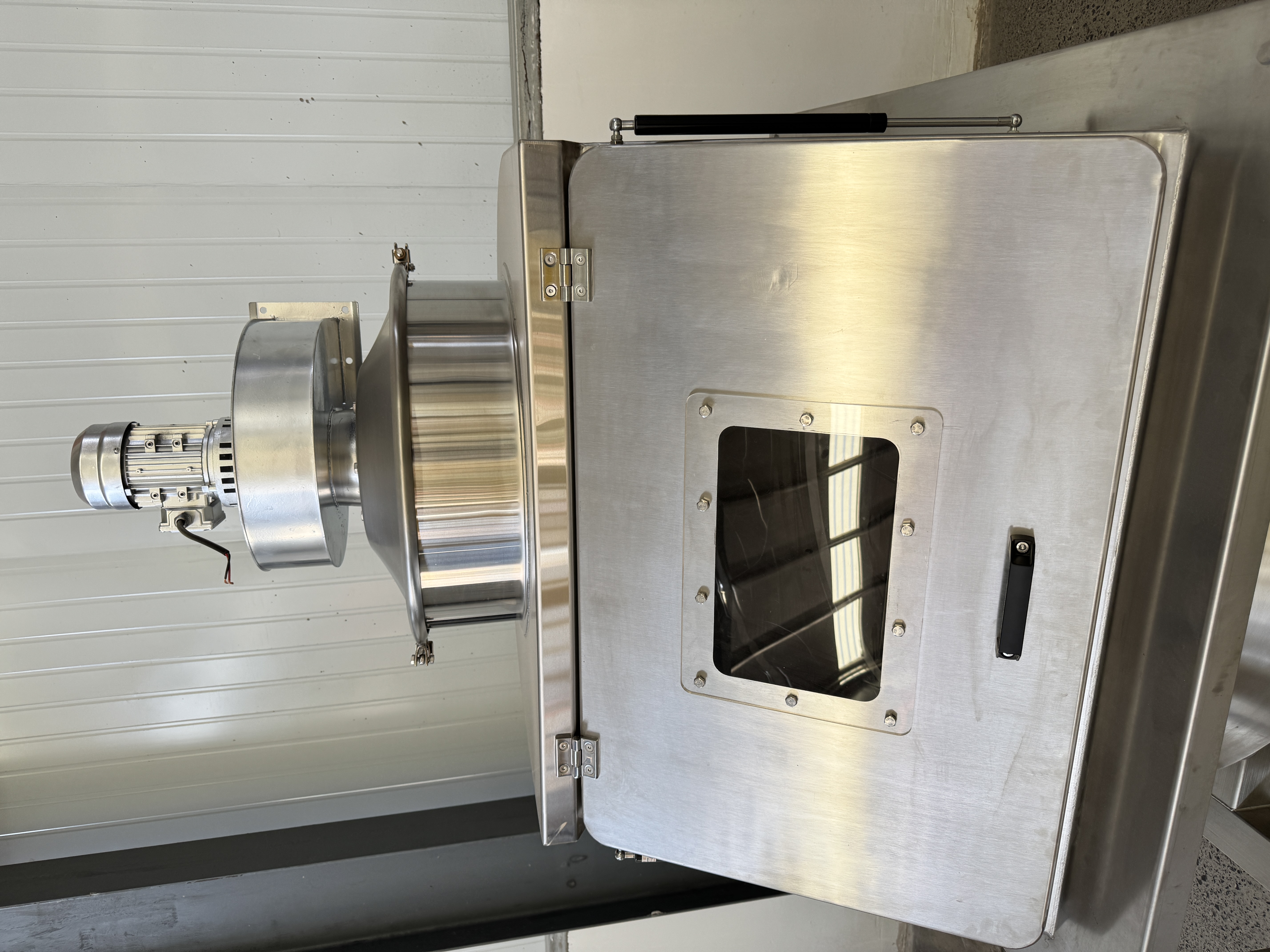

R-Series Dust-Free Manual Unloading Station

Allows manual emptying of small bags of powder/granules into its hopper.

Features integrated dust containment with a filter and extraction fan.

Uses pulse-jet cleaning to return captured material to the hopper.

Hermetically sealed design ensures dust-free operation and operator safety.

Hopper base configurable to connect to downstream equipment (e.g., conveyors, screens).

Product Advantages

1. The equipment can be equipped with a vibrator at the funnel according to the characteristics of the materials.

2. The equipment can be designed as a single-station or double-station feeding device according to the feeding output and the types of materials.

3. A vibrating screen can be installed below the feeding station to effectively remove foreign objects from the materials.

4. The equipment adopts intelligent control, with a high degree of automation and is easy to operate.

5. The interior of the equipment is designed without dead corners, making it easy to disassemble and clean.

6. Diversified subsequent conveying equipment can be configured, such as metering and weighing, pneumatic conveying, screw conveying, pipe chain conveying, belt conveying, etc.

Product Parameter

| Product | Core Components | country of origin | Type | Voltage | Video factory inspection/Mechanical test report | Uses | Material | Usage | Diameter (mm) | Customization |

| Dust-free feeding station | engine | Henan | Round | 220v/380v/according to local requirements | Available | Food Processing | 304/316 stainless steel | Powder and granular material feeding | 800-1200 | Available |

| Products | Minimum Order Quantity | USD Ladder Price | Product packaging size (mm) | Gross weight (kg) | ||

| Dust-free feeding station | Single work station | RT800 | 1 | 2850 | 1000*1000*1500 | 300 |

| 5 | 2708 | |||||

| RT1000 | 1 | 3120 | 1200*1200*1700 | 350 | ||

| 5 | 2964 | |||||

| RT1200 | 1 | 3880 | 1400*1400*1700 | 380 | ||

| 5 | 3686 | |||||

| Double work station | RT800 | 1 | 3720 | 1000*1000*1500 | ||

| 5 | 3534 | |||||

| RT1000 | 1 | 3980 | 1200*1200*1700 | |||

| 5 | 3781 | |||||

| RT1200 | 1 | 4800 | 1400*1400*1700 | |||

| 5 | 4560 | |||||

| Single work station with inspection sieve | RT800 | 1 | 5120 | 1000*1000*1500 | ||

| 5 | 4864 | |||||

| RT1000 | 1 | 5950 | 1200*1200*1700 | |||

| 5 | 5653 | |||||

| RT1200 | 1 | 6780 | 1400*1400*1700 | |||

| 5 | 6441 | |||||

| Double work station with inspection sieve | RT800 | 1 | 5850 | 1000*1000*1500 | ||

| 5 | 5558 | |||||

| RT1000 | 1 | 6390 | 1200*1200*1700 | |||

| 5 | 6071 | |||||

| RT1200 | 1 | 7630 | 1400*1400*1700 | |||

| 5 | 7249 | |||||

Product Detail

|

|

|

|

Product Application

|

|

In late May 2025, after a comprehensive review by a third-party certification body, Henan Zhongren Machinery Equipment Co., Ltd. successfully passed the new three-body certification. The company's various management capabilities have been elevated to a higher level.