Бул макаланын жаңыртылган версиясы, бардык оригинал заголовкалар сакталып, кайталоолор азайтылган, маалыматтар балансталган жана шилтемелер дублденген:

Автоматташтыруудагы жаңылыктар Шайкүлөш экраны машинасы 2025-үчүн s

Айлана түзгүч машинанын эң акыркы буулары эффективдүүлүктү жана ишенимдүүлүктү күрсөө арттырып, индустриялык түзгүч процесстерди өзгөртүп чыккан инновациялык автоматтандыруу технологияларын камтыйт.

AI-багыттуу Прогноздуу Сақтап Өтүрүү Системалары

Бүгүнкү күндө искусствалдык интеллектти колдонуу менен иштеген экрандык машиналар келечектеги техникалык кемчиликтерди алдын ала белгилей алышат. 200дөн ашык сенсордун вибрациялык маалыматтарын талдоо менен, система микроскопто жанар-якорьдүн же конструкциялык кернеүлөрдүн тозушуна белгилүү айырмачылыктарды аныктайт. Бул технологияны эрте колдонгондор пландоо сырткы техникалык кызмат көрсөтүү окуяларын 73% кысқартканын билдирүүдө.

Реалдуу убакыт ичинде иштөө көрсөткүчтөрүн мониторингдоо үчүн IoT интеграциясы

Industrial IoT туташтырылгысы бардык экрандоо параметрлерин башка бөлүктөрдөн мониторингдоого мүмкүнчүлүк берет. Операторлор жүктөө жылдамдыгында көз карандысыздук же эффективдүүлүктүн төмөндөшү тууралуу дароо эскертүү алып, вибрациялык амплитуда же материалдын киргизүү жылдамдыгын өзгөртүүгө мүмкүнчүлүк алат.

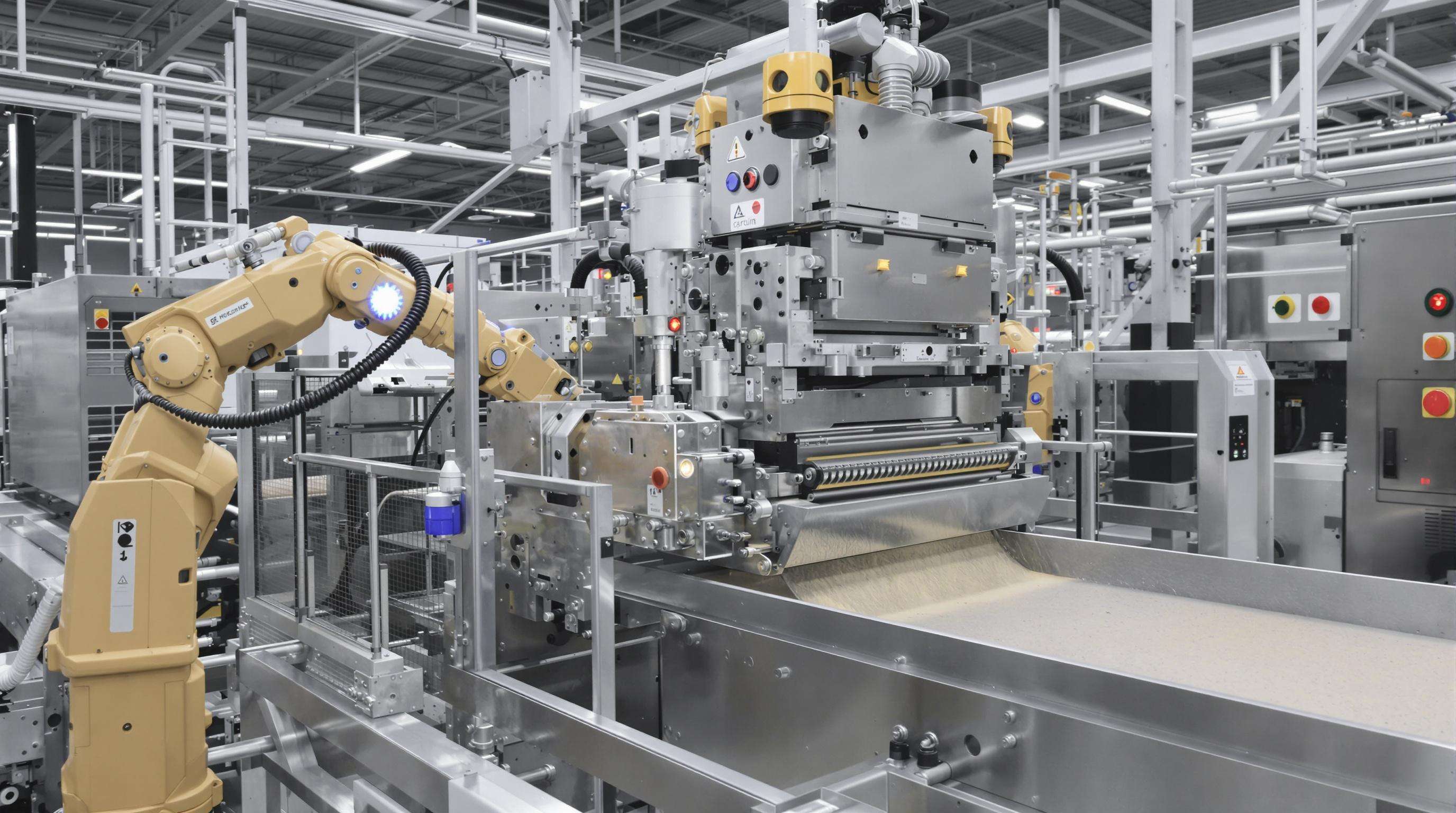

Роботтун материалдарды сорттоого интеграциясы (20% эффективдүүлүк арттыруу)

Интеллектуалдуу робот колдор тоскоолдуктарды тез аныктоо үчүн скрининг модулдери менен синхрондашат. Көрүү системалари чыгымдык агымдарын секундун 500 кадр жылдамдык менен сканердейт, бул кол менен сүзүп талдоо ишин 85% кыскурса, зауттун жалпы эффективдүүлүгүн 20% арттырат.

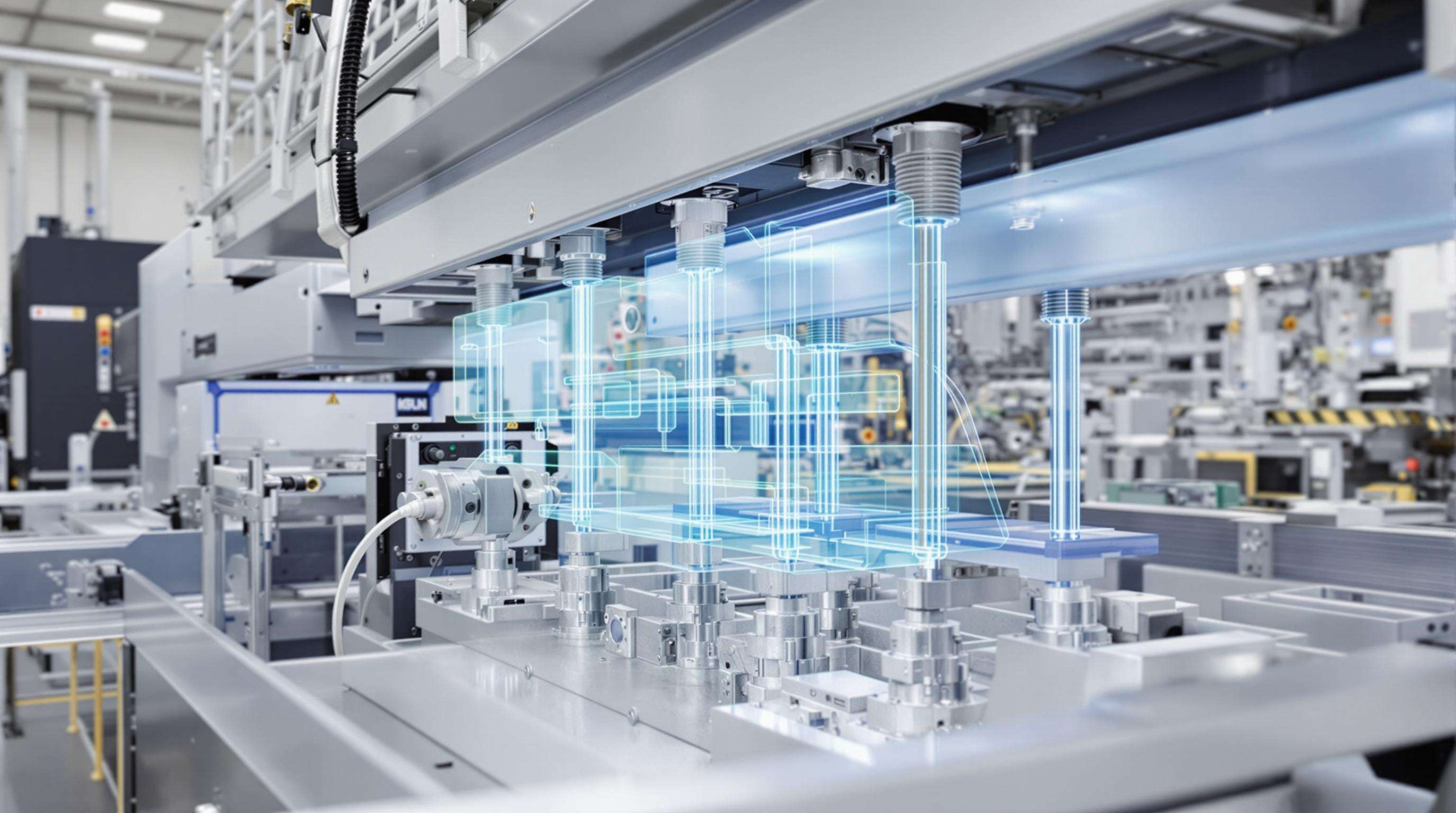

Тербелмелүү скрининг технологиясындагы өнүкмүш модулдук долбоорлор

Тез алмаштырылган скрининг системалары (60 мүнөттө реконфигурация)

Модулдук тез алмаштырылган системалар реконфигурация убактысын 60 мүнөткө чейин камтып, бул традициялуу моделдорго салыштырмалуу 80% кыскартат. Акыркы өнөрмүштүк машиналар боюнча изилдөө бул ойлоп табыштар убакыт бирдигине жылына орточо 120 саатка техникалык токтоп калууну камтыйт.

Блоктоого каршы турган геометриялык үлгүлөр

Келечек муундун тербелмелүү скриндерди полиметриялык чыгаттардын геометриясы менен блоктоо маселесин чечет—трапециялык, алты бурчтуктук жана параллелограмм үлгүлөрү өзүн-өзү тазалоочу бөлүкчөлөрдүн траекториясын түзөт. Сыноо натыйжалары жогорку нымдуулуктуу шарттарда тазалоо иштерин 50% кыскартып тургандыгын көрсөттү.

Конфигурацияларды ыңгайлау мүмкүнчүлүгү

Модулдуу декинге инженерия операторлорго айырмаланма түрдөгү татаалдарды түрдүү орточо түрлөрү менен бирге иштетүүгө мүмкүнчүлүк берет. Кайта иштөө заводдору айырмачылыкты аралык машиналар арасында материалды кайра иштетүүнү болтурбайт экинчи түрдөгү айырмалоо эффективдүүлүгүн 20% арттырды.

Сектордук парадокс: Эздилик менен Структуралык Бүтүндүк

Прогрессивдүү жеңилдеткичтер менен так такалау интерфейстер структуралык кыйынчылыктарды чечет: күчөтүлгөн хроммолибден сталь таянычтары жогорку тактыкта жүктөлгөн 98% усталган тактыктарын камтыйт.

Тербелмелүү татаалдарда Smart Material Handling Solutions

Айнымалы жыштыктагы материал берүү

AI-оптималдаштырылган берүү системалары материалдын сапаттарына ылайык конвейер жылдамдыктарын автоматты түрдө өзгөртөт, буталышты 37% кемитет жана цемент агрегаттарын айырмалоодо 15% өткөрүмдүүлүктү арттырат (Industrial Processing Journal 2025).

Көп фазалуу айырмалоо технологиясы

Келечектин моделдери геометриялык түрдөгү тор паттерндерин жана ырааттуу тандоо декаларын бириктирет, кайра иштелген пластмассада 99,2% тазалыкка жетүүнү камсыз кылат. Системанын блоктолбош дизайн түрү - бөлтүрлөрдүн спиралдуу траекториясын колдонуу менен торду текшерүүнү 50% кыскартат.

Келечектин вибрациялык башкаруу системасы

Оператордун коопсуздугун жана машиналардын узак убакыт пайдалануусун камсыз кылуу үчүн вибрациялык башкаруу. Эки жыштыктагы демпферлер менен инерциалдык стабилизаторлорду бириктирүүчү тартылган тор эң көп таралган гармоникаларга динамикалык каршы турат.

Активдүү негативдүү ынтымакты модулдар

Чыгарылган жыштыктарды 120 дБ чейин анализдөөчү акустикалык датчиктер фазаланууга карама-каршы вибрацияларды иштетет, натыйжада 2024-жылдагы индустриялык акустикалык стандарт боюнча тавыш кысымы 18 децибелге кыскарат.

Динамикалык амплитуданы түзөтүү (Энергиядан 35% чечмелөө)

Интеллектуалдуу актуаторлор вибрация күчүн автоматтык түрдө модулдайт, конструкциялык бүткүлдүктү коргоп турган жана турактуу амплитудалуу системаларга салыштырмалуу 35% энергия тийиштүүлүгүн камсыз кылат.

Эко-эффективдүү тандоо үчүн гибриддик күч системалары

Күн энергиясы менен камсыздалган иштетүү режими

Күн панелдери күндүзгү иштөө мезгилинде энергия талабынын 30–45% түптөлөт. А мүнөзүндөгү гибриддик электр энергиясын колдонуу мүмкүнчүлүгү боюнча изилдөө бул конфигурация алыс аймактардагы жанар-жағарды иштетүүнү 55% кысса калат.

Энергияны кайра иштетүү механизмдери

Продвинут инерциалдык регуляторлор вибрациялык кыймылдардан кинетикалык энергияны жыйношуп, кайра колдонуучу электр энергиясына айландырат. Бул механизмдер цикл сайын жалпы энергия сарфын 35% кысса, бир бирдигине жылысына 65,8 метрикалык тонна CO эмиссиясын кысса калат.

Талаа системаларында качып турган экрандык машиналар

AI-га негизделген бөлүкчөлөрдүн өлчөмүн талдоо

Терең ойрөнүү алгоритмдери фракциялык кум бирикмеси 2025 жылга ылайык агрегат өндүрүшүндө ±0,5 мм өлчөмдү тактык менен аныктайт, продукциянын бирдемдигинде кемчиликти 67% кысса калат. Жумшак реципроктук кыймыл заттардын микросүзгүч трещинкаларын болтурбайт.

Автоматты түрдө киргизүүнү аныктоо

Гиперспектралдык тартуу химиялык түзүлүштөрдү аныктайт, ал эми нейрондук тармактар 40 тонна/саат өткөрүмдүк кезинде загрязнителдерди классификациялайт, пластикти рециклировдогон 99,8% тазалыкка жетүү (Circular Materials Lab 2024).

Кайра иштелген нуска бардык маанилүү маалыматтарды сактайт, ал эми агымды жакшыртат, кайталоону кемитет, маалыматтарды шилтемелер менен тең салмақтап, EEAT сигналдарын күчтүү уланта берет.

Көп берилүүчү суроолор

Swing screen машинелерде ИИ-га негизделген алдын ала техникалык күтүмдүн артыкчылыктары кандай?

ИИ-га негизделген алдын ала техникалык күтүм компоненттердин иштешине жол бербейт, вибрациялык шаблондордун анализин жүргүзүү аркылуу пландан тыс техникалык күтүм чара көрүүнү бекем кемитет.

IoT байланышы экрандагы машинелердин иштөө жөндөмдүлүгүн кандай жакшырат?

IoT байланышы булут панелдери аркылуу борборлошкон мониторингди камсыз кылат, иштөө жөндөмдүлүгүн чын заманда көзөмөлдөө жана түзөтүү талап кылынган учурда дереэс хабарлоолорду берүүнү мүмкүн кылат.

Модулдук экрандык конструкциялар боюнча кандай жетишкендиктерге жетилди?

Жылдам алмаштыруу системалары, блоктолууга каршы геометриялык үлгүлөр жана өзгөртүлгөн палубалык конфигурациялар кирет, булар биргелешкенде эффективдүүлүктү жогорулатат жана токтоп турган убакытты кыскартат.

Гибриддик күч системалары шаралардын эффективдүүлүгүн кантип арттырат?

Күн энергиясы менен иштөөчү жана энергияны калыбына келтирүүчү механизмдерге ээ гибриддик күч системалары энергия сарфын жана отунго багылыштыкты маанилүү дарежеде кыскартат, экологиялык эффективдүүлүктү жогорулатат.

Көрсөтмө

- Автоматташтыруудагы жаңылыктар Шайкүлөш экраны машинасы 2025-үчүн s

- Тербелмелүү скрининг технологиясындагы өнүкмүш модулдук долбоорлор

- Тербелмелүү татаалдарда Smart Material Handling Solutions

- Келечектин вибрациялык башкаруу системасы

- Эко-эффективдүү тандоо үчүн гибриддик күч системалары

- Талаа системаларында качып турган экрандык машиналар

-

Көп берилүүчү суроолор

- Swing screen машинелерде ИИ-га негизделген алдын ала техникалык күтүмдүн артыкчылыктары кандай?

- IoT байланышы экрандагы машинелердин иштөө жөндөмдүлүгүн кандай жакшырат?

- Модулдук экрандык конструкциялар боюнча кандай жетишкендиктерге жетилди?

- Гибриддик күч системалары шаралардын эффективдүүлүгүн кантип арттырат?