The Importance of Efficient Sieving With unrivaled classifying precision for all material types, the Tumbler Screen utilizes a singular, patented classifying method that combines straight-line, and circular motion to simulate the manual classifying p...

VIEW MORE

Sanitation and Compliance Regulations The cosmetics industry has high standards for hygiene in the production of equipment. There are also regulatory standards that show production equipment that touches raw materials must be non-corrosive, non-toxic...

VIEW MORE

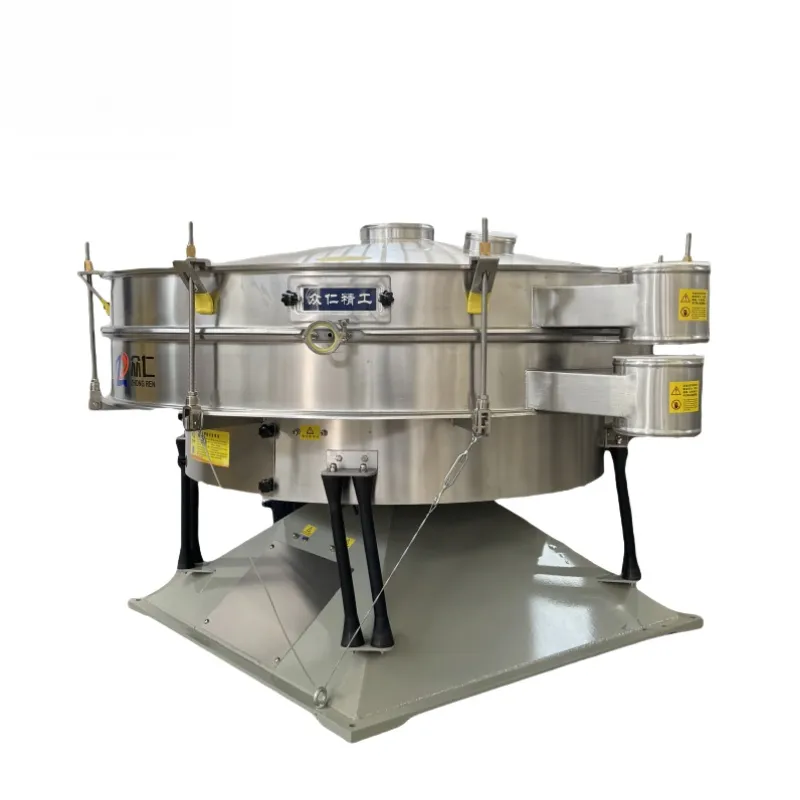

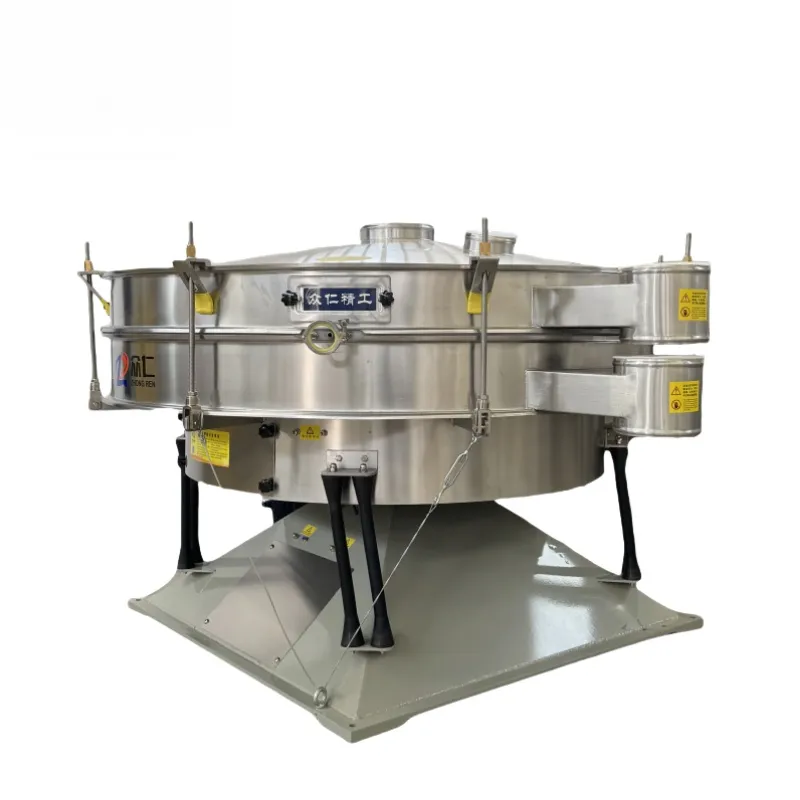

Technological Core and Food Grade Design In food processing, the vibrating sieve is one of the most important pieces of equipment, and its food-grade design is one of the most important factors that helps the business adapt to the strict hygenic and ...

VIEW MORE

Benefits of Using Vibrating Screens in the Chemical Industry The world's industrial production cannot function without the chemical industry. It has the largest volume of production. Screening of materials is an important part of the chain which dete...

VIEW MORE

The Part Swing Machines Play In Material Handling Swing machines are essential in modern industry material handling and are helping to close the gaps that older screening equipment fail to address. They combine precision and efficiency unmatched by o...

VIEW MORE

How Oscillating Screens are Used in Pharmaceutical Manufacturing With the advancements made in the pharmaceutical industry, there are now strict industry regulations that must be complied with. In order to meet these industry regulations, oscillating...

VIEW MORE

Checking and Maintaining Equipment If you want to operate a vibrating machine safely, you need to do regular inspections and maintenance. Before using a machine, you should check for loose bolts, damaged wires, and broken screens. These proble...

VIEW MORE

The Importance of Selecting Quality Materials The journey of wear resistance in vibrating screens begins with the first materials used, and this is where strong knowledge of industrial equipment manufacturing becomes very valuable. Tough manganese st...

VIEW MORE

Introduction to Vibrating Screen Applications For the food and beverage industry and so many more, a vibrating screen is a crucial part of the operation because it separates the materials and helps keep the operation organized. It regulates the vibra...

VIEW MORE

The pharmaceutical industry must navigate a world of consistency, safety, and compliance. Among the top pieces of equipment helping the pharmaceutical industry keep production on schedule are sifter machines. Why are pharmaceuticals so heavily reli...

VIEW MORE

Understand Safety Guidelines Regarding Sifter Machines There are some safety standards that apply to all sifter machines. This includes food processing vibratory screens, swing sieves, and other sifter machines that are used in the food, drugs, and...

VIEW MORE

Understanding the Swing Screen Machine: Core Components and Their Role in Performance Key components of the Swing Screen Machine impacting performance The Swing Screen Machine's operational efficiency hinges on three critical systems: Drive mechan...

VIEW MORE