Core Components of Modern Material Conveying Systems

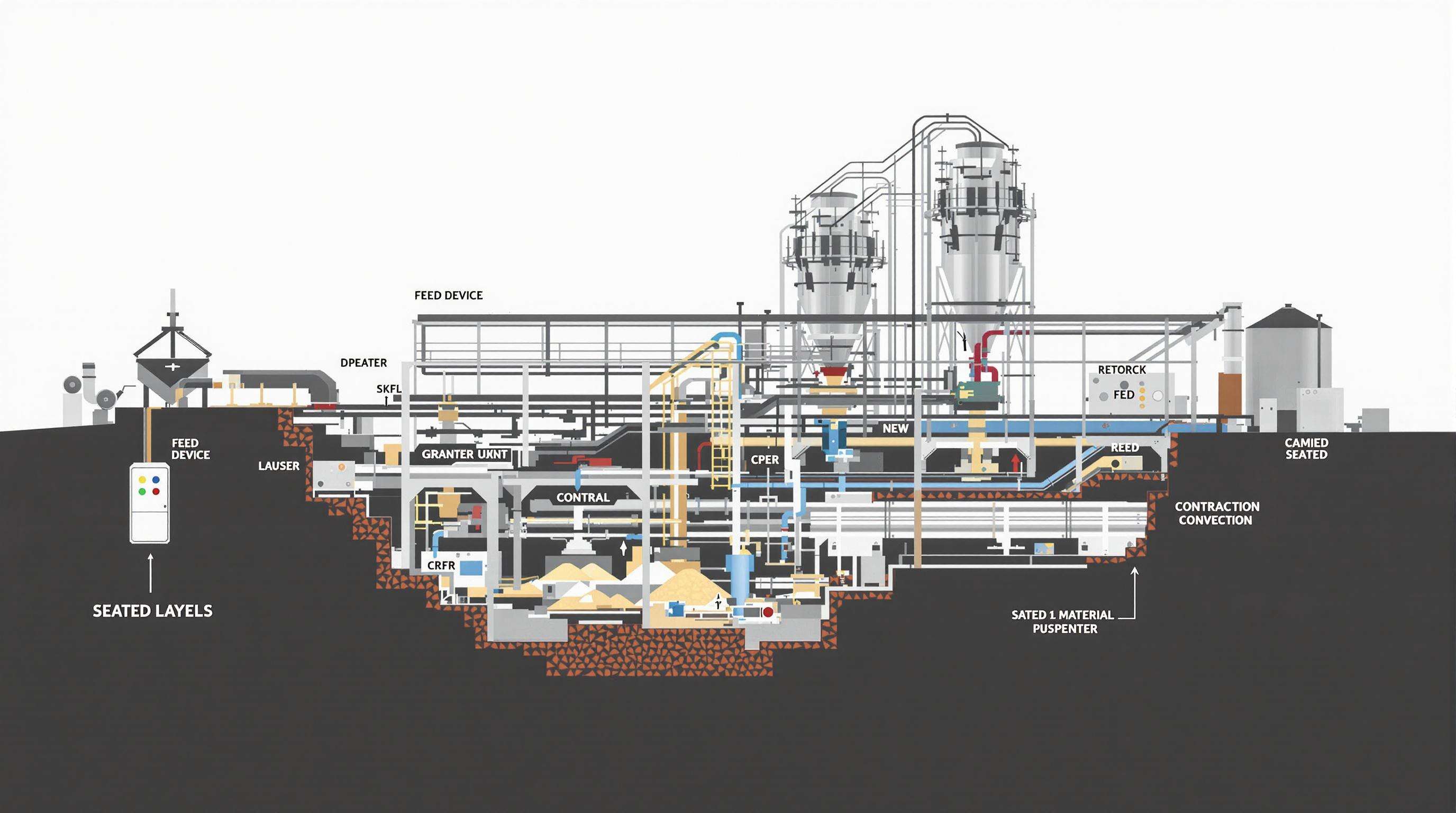

Material properties fundamentally shape conveying system requirements. Particle size, abrasiveness, weight, and fragility determine specifications ranging from belt material selection to operational speeds. Understanding these factors prevents inefficiencies, product damage, and system downtime.

Movement parameters like travel distance, elevation changes, and routing dictate system architecture. Designers must consider material transfer points, throughput fluctuations, and start/stop frequencies that influence structural load capacities.

Two primary pneumatic systems showcase core engineering principles:

- Positive pressure systems propel materials over extended distances using compressed air

- Vacuum systems leverage suction for shorter hauls with superior containment safety

Critical components across all conveyors include:

- Feed devices introducing materials into the system (rotary valves, venturi units)

- Sealed conveying lines maintaining directional flow

- Separation units isolating materials at discharge (cyclones, filters)

Layout geometry directly impacts performance, as frequent vertical ascents or tight bends elevate component stress and airflow turbulence.

Technological Innovations Elevating Material Conveying Efficiency

IoT Integration and Sensor Technologies for Real-Time Monitoring

Embedded IoT sensors transform material conveying systems into intelligent networks capable of monitoring vibrations, temperature, and load distribution 24/7. Pharmaceutical facilities leverage RFID trackers to maintain sterile material handling conditions throughout transfer processes.

AI-Driven Predictive Maintenance in Conveyor Operations

Artificial intelligence analyzes vibration patterns and thermal imaging data to forecast mechanical failures 4-8 weeks before occurrence. A quarry implementation demonstrated 45% fewer unplanned shutdowns after adopting AI diagnostics. Machine learning algorithms continuously refine failure prediction accuracy.

Control Systems Optimization for Warehouse Management

Centralized control platforms synchronize multiple conveyor subsystems through programmable logic controllers (PLCs). In distribution centers, optical sorters integrated with warehouse management software achieve 99.8% routing accuracy for packages.

| Optimization Parameter | Traditional Systems | Modern Control Systems | Improvement |

|---|---|---|---|

| Sorting Accuracy | 87% | 99.8% | +14.7% |

| Energy Consumption | 31 kWh/ton | 20 kWh/ton | -35% |

| Manual Interventions | 15/hour | 2/hour | -87% |

Energy Efficiency Strategies in Material Conveying Systems

Sustainable Material Handling for CO₂ Emission Reduction

Modern conveying systems deploy energy recovery mechanisms like regenerative braking that capture kinetic energy during deceleration. Low-power component designs—including high-efficiency motors—reduce baseline energy consumption by 30-40%.

Case Study: Power Conservation in Mining Conveyors

A mineral extraction site implemented variable frequency drives (VFDs), reducing motor energy consumption by 18%. Regenerative systems on decline conveyors reclaimed 1.4 GWh annually—equivalent to 900 metric tons of CO₂ reduction.

Industry 4.0 Application in Centralized Material Conveying

Industry 4.0 revolutionizes centralized material conveying through interconnected cyber-physical systems. These intelligent frameworks allow centralized control hubs to dynamically coordinate multiple production zones.

Machine Learning for Haulage System Optimization

Machine learning algorithms transform bulk material haulage by analyzing historical performance data with real-time inputs like weight distribution and belt tension. These systems reduce unplanned downtime by 35% in cement plant applications.

Modular Architecture for Flexible Bulk Material Handling

Modular conveyor configurations enable rapid system reconfiguration to accommodate changing production demands. This architectural approach reduces capital expenditure by 30% compared to fixed installations.

Data-Driven Improvements in Throughput Accuracy

Centralized conveying systems utilizing real-time sensor networks achieve throughput precision through continuous data synthesis. In food-grade handling environments, this precision reduces product giveaway by an average 17 tons monthly.

Industry Paradox: Automation vs. Workforce Transformation

The automation surge creates demand for specialized technicians who oversee algorithm training and robotic systems. Facilities implement comprehensive retraining programs that transition 65% of displaced workers into higher-value positions.

Cost-Benefit Analysis of Centralized Conveying Solutions

ROI Metrics from Operational Efficiency Gains

Centralized conveying systems deliver measurable returns by slashing operational expenses. These efficiency gains yield ROI periods under 18 months for most mineral processing installations.

Lifecycle Costing for Crusher and Conveyor Integration

Properly integrated systems demonstrate 22% lower total ownership costs across 15-year horizons. Key savings stem from synchronized wear components and adaptive speed controls.

FAQ

What are the core components of modern material conveying systems?

The core components include feed devices, sealed conveying lines, and separation units. These components ensure efficient material introduction, flow maintenance, and material isolation at discharge points.

How does Industry 4.0 apply to material conveying systems?

Industry 4.0 in material conveying involves the use of interconnected cyber-physical systems to enhance control and coordination across multiple production zones, using real-time data and machine learning.

What benefits does AI provide in conveyor operations?

AI in conveyor operations helps predict maintenance needs by analyzing vibration patterns and thermal imaging, reducing unplanned shutdowns and enhancing the accuracy of failure predictions.

How do modern conveying systems reduce energy consumption?

Modern systems use energy recovery mechanisms and low-power component designs, such as high-efficiency motors, to reduce energy consumption by 30-40%.

What are the advantages of modular conveyor architecture?

Modular conveyor architecture allows rapid reconfiguration for different production needs, reducing capital expenditure by 30% compared to fixed installations.