Podstawowe zasady działania Systemy transportu materiałów

W jaki sposób systemy pneumatycznego transportu wykorzystują energię powietrza

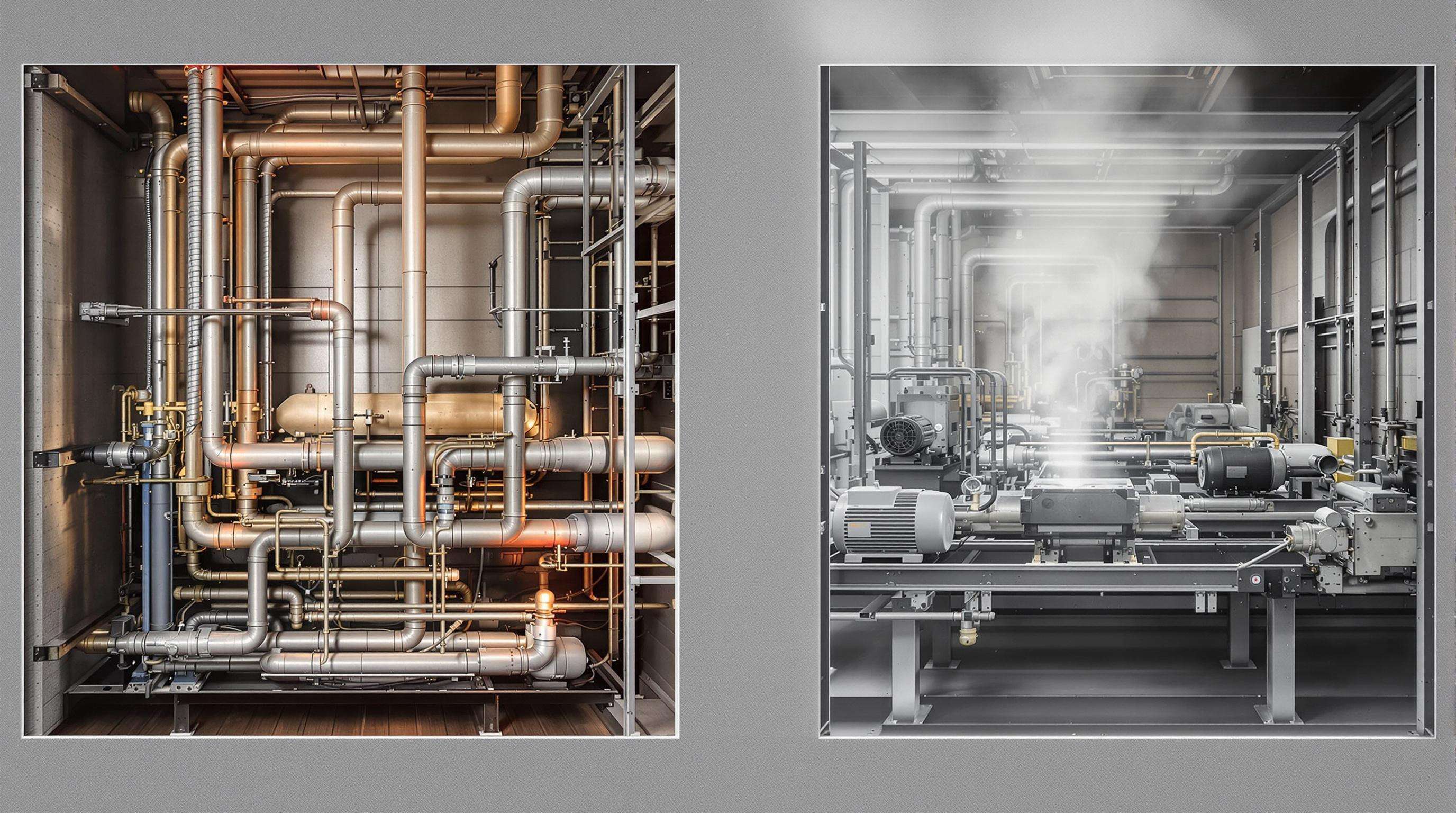

Pneumatyczne transportowanie materiałów w rurach osiąga się dzięki zastosowaniu przepływów powietrza lub gazu o wysokim ciśnieniu, które są utrzymywane jako przepływy o dużej prędkości, przenoszące i popychające cząstki. Istnieją dwa główne sposoby: systemy przepływowe lub o nadciśnieniu wypychają materiał na zewnątrz za pomocą kompresorów (idealne na dłuższe odległości), natomiast systemy podciśnieniowe wciągają materiał do centralnego miejsca docelowego (co zmniejsza ryzyko wycieku materiału na zewnątrz). Charakterystyka przepływu oraz jego skuteczność są silnie wpływane przez właściwości powietrza, takie jak wilgotność i temperatura. Odpowiednie proporcje powietrza do materiału utrzymują ruch w linii – typowa prędkość 15–35 m/s przy niskoprędkościowym transporcie zapobiega osadzaniu się i degradacji delikatnych proszków.

Mechanizmy Ruchu Mechanicznego w Systemach Transportu

To są *mechaniczne* przenośniki, a nie ciśnieniowe. Układy taśmowe transportują materiały sypkie w poziomie lub w pionie za pomocą napędzanych taśm, a materiały równie często mogą być rozsypane na boki (i na podłogę), jak i dostarczone we właściwe miejsce. Przenośniki śrubowe wykorzystują wirujące śruby spiralne i mają niewiele ruchomych części, co czyni je szczególnie efektywnymi. Podnośnice kubłowe służą do pionowego transportu materiałów w kubłach poruszających się po łańcuchu. Właściwości materiału decydują o doborze materiałów: materiał ścierny wymaga kombinacji stal-stal dla dysz i siedzisk zaworów w celu zapewnienia długiej trwałości, podczas gdy bardziej kruche produkty mogą być używane z dyszami i siedziskami zaworów ceramicznymi. Regulatory prędkości taśmy kontrolują stałą prędkość przepływu i zapobiegają zatykaniu.

Podstawowe różnice w konstrukcji pomiędzy typami systemów

| Aspekt projektowy | Systemy pneumatyczne | Układów mechanicznych |

|---|---|---|

| Układ komponentów | Liniowe rurociągi z minimalną liczbą zakrętów | Złożony zespół silników/taśm |

| Wymagania dotyczące przestrzeni | Kompaktowa, elastyczna trasa | Stała trasa wymagająca większej powierzchni podłogowej |

| Interakcja z materiałem | Zawieszenie cząstek w powietrzu | Bezpośredni kontakt powierzchniowy |

| Dynamika operacyjna | Różnice ciśnienia generują przepływ | Siła mechaniczna obrotowa/liniowa |

Projekty pneumatyczne doskonale sprawdzają się w środowiskach niebezpiecznych/narażonych na kurz dzięki skutecznemu zawieraniu, natomiast systemy mechaniczne radzą sobie z materiałami o wyższej gęstości. Zużycie energii znacząco się różni: operacje pneumatyczne wymagają ciągłego sprężania powietrza (3-4 razy więcej kW/tonę), podczas gdy napędy mechaniczne pobierają szczytowe moce jedynie podczas przyspieszania.

Porównanie możliwości transportu materiałów

Nienaruszalność produktu w procesach transportu pneumatycznego

Systemy pneumatyczne zachowują jakość materiału, szczególnie przy nietartych materiałach sypkich, takich jak dodatki do żywności czy proszki farmaceutyczne. Dobór prędkości powietrza ma kluczowe znaczenie – zbyt duża siła niszczy delikatne elementy, a zbyt mały przepływ powoduje zatykanie się instalacji. Systemy próżniowe zmniejszają ryzyko utleniania dla wrażliwych związków, a konfiguracje fazowe rozrzedzone najlepiej sprawdzają się przy proszkach o swobodnym przepływie.

Zgodność materiałów z systemami mechanicznymi

Przenośniki mechaniczne transportują różne materiały poprzez bezpośredni kontakt. Przenośniki śrubowe przemieszczają proszki o zawartości wilgoci ≥35%, natomiast taśmy radzą sobie z grubymi frakcjami, takimi jak trociny. Gęstość nasypowa (≥80 lb/ft³) wskazuje na płynną pracę, a specjalistyczne konstrukcje (np. przenośniki drążkowe tubowe) służą do transportu proszków wrażliwych na elektrostatykę.

Ograniczenia i wyzwania ze względu na rodzaj materiału

| Właściwość materiału | Ograniczenie pneumatyczne | Wyzwanie mechaniczne |

|---|---|---|

| Wysoka ścieralność | Erozja rurociągu (>0,5 mm/rok zużycia) | Degradacja śruby/taśmy |

| Lepkowość | Ryzyko zapychania filtrów | Nadmiar w martwych strefach |

| Czułość na temperaturę | Ciepło powstałe przy sprężaniu | Ciepło tarcia |

| Potencjał wybuchowy | Ryzyko zapłonu elektrostatycznego | Punkty generowania ciepła |

Materiały higroskopijne (>1,5% powinowactwa do wilgoci) często wymagają osuszaczy powietrznych do transportu pneumatycznego, podczas gdy materiały włókniste mogą się zaplątywać w śrubach bez zmodyfikowanych projektów łopatek.

Efektywność energetyczna w systemach transportu materiałów

Zużycie energii: pneumatyczne kontra mechaniczne

Systemy pneumatyczne zużywają 2-3 razy więcej energii na tonę ze względu na sprężanie powietrza (15-30% traconego jako ciepło). Konwejery mechaniczne z napędami o zmiennej częstotliwości dopasowują moc do zapotrzebowania, zmniejszając zużycie o 25-40% podczas pracy przy obciążeniu częściowym.

Wskaźniki Efektywności Operacyjnej

| Metryczny | Układów mechanicznych | Systemy pneumatyczne |

|---|---|---|

| Średnie kWh/tona-mila | 0,4-0,8 | 1.1-2.3 |

| Potencjał regeneracji | 15-25% | 5-10% |

| Straty spowodowane konserwacją | 12-18% | 20-28% |

Strategie optymalizacyjne, takie jak algorytmy kontroli prędkości, mogą zmniejszyć zużycie energii w taśmociągach o 30-35%. Regularna konserwacja zapobiega spadkom wydajności spowodowanym przez zużyte komponenty.

Koszty instalacji i wymagania serwisowe

Przegląd początkowych kosztów inwestycyjnych

Systemy pneumatyczne są o 40-50% droższe przy zakupie początkowym ze względu na kompresory i filtry. Instalacje mechaniczne wiążą się ze zmianami konstrukcyjnymi i pracą ręczną, przy czym dostosowania infrastruktury pochłaniają 25-35% budżetu.

Konserwacja długoterminowa

Jednostki pneumatyczne wymagają wymiany filtrów co kwartał oraz kontroli rurociągów (7 500–15 000 USD/rok). Układy mechaniczne wymagają regulacji pasków i smarowania (5 000–9 000 USD/rok). Koszty utrzymania pneumatyki są o 20–30% wyższe w ciągu pięciu lat ze względu na zużycie spowodowane ciśnieniem powietrza.

Kompromis między kosztem a elastycznością

Rozwiązania mechaniczne oferują o 30% niższe koszty całkowite, ale są mniej elastyczne. Systemy pneumatyczne zapewniają elastyczność i szybszy zwrot z inwestycji (18 miesięcy) w dynamicznych środowiskach.

Zastosowania i przydatność systemów transportowych

Scenariusze operacyjne sprzyjające zastosowaniu pneumatyki

Systemy pneumatyczne doskonale sprawdzają się w przemyśle spożywczym i farmaceutycznym, gwarantując higienę i delikatny transport. Ich zamknięte rurociągi zapobiegają zanieczyszczeniom, a elastyczna trasa dopasowuje się do skomplikowanych układów.

Zastosowania przemysłowe mechaniki

Przenośniki mechaniczne dominują w górnictwie, budownictwie i rolnictwie. Układy pasowe transportują globalnie ponad 90% wydobywanych surowców, a przenośniki kubłowe skutecznie radzą sobie z transportem pionowym.

Studium przypadku: Zakład przetwórstwa spożywcego

Piekarnia wykorzystywała systemy pneumatyczne do transportu mąki/cukru (zapewniając czystość) oraz mechaniczne przenośniki kubłowe do przewożenia towarów pakowanych. Ta hybrydowa metoda zmniejszyła zanieczyszczenia o 78%, jednocześnie obniżając koszty energii o 45%.

Kryteria wyboru systemów transportu materiału

Główne czynniki decydujące

Dystans, właściwości materiału i środowisko wpływają na wybór. Systemy pneumatyczne nadają się do dłuższych odległości, natomiast systemy mechaniczne lepiej radzą sobie z gęstymi lub ściernymi materiałami. Kontrola pylenia i ograniczona przestrzeń również wpływają na projektowanie.

Przyszłe trendy

IoT umożliwia monitorowanie w czasie rzeczywistym, a napędy z regulowaną częstotliwością zwiększają efektywność. Projekty modułowe pozwalają na szybką przebudowę, podczas gdy Industria 4.0 wspiera utrzymaniowe predykcyjne poprzez uczenie maszynowe.

Często zadawane pytania: Systemy transportu materiałów

Jakie są główne typy systemów transportu materiałów?

Główne typy to systemy pneumatyczne i mechaniczne, z których każdy ma swoje unikalne zalety i metody działania.

Jak działają systemy transportu pneumatycznego?

Systemy pneumatyczne wykorzystują sprężone powietrze lub gaz do transportu materiałów rurociągami, wykorzystując stosunek powietrza do materiału do skutecznego przemieszczania.

Jakie czynniki wpływają na wybór między systemem pneumatycznym a mechanicznym?

Główne czynniki to rodzaj materiału, odległość transportu, efektywność energetyczna, koszt instalacji oraz warunki środowiskowe.

Czy systemy pneumatyczne są bardziej efektywne energetycznie niż systemy mechaniczne?

Zazwyczaj systemy pneumatyczne zużywają więcej energii ze względu na sprężanie powietrza, podczas gdy systemy mechaniczne często korzystają z energooszczędnych rozwiązań, takich jak przemienniki częstotliwości.

Które branże najbardziej korzystają na zastosowaniu systemów pneumatycznych?

Systemy pneumatyczne są idealne w branżach takich jak przetwórstwo spożywcze i farmacja, gdzie higiena i delikatne obchodzenie się z materiałami są krytyczne.

Spis treści

- Podstawowe zasady działania Systemy transportu materiałów

- Porównanie możliwości transportu materiałów

- Efektywność energetyczna w systemach transportu materiałów

- Koszty instalacji i wymagania serwisowe

- Zastosowania i przydatność systemów transportowych

- Kryteria wyboru systemów transportu materiału

-

Często zadawane pytania: Systemy transportu materiałów

- Jakie są główne typy systemów transportu materiałów?

- Jak działają systemy transportu pneumatycznego?

- Jakie czynniki wpływają na wybór między systemem pneumatycznym a mechanicznym?

- Czy systemy pneumatyczne są bardziej efektywne energetycznie niż systemy mechaniczne?

- Które branże najbardziej korzystają na zastosowaniu systemów pneumatycznych?