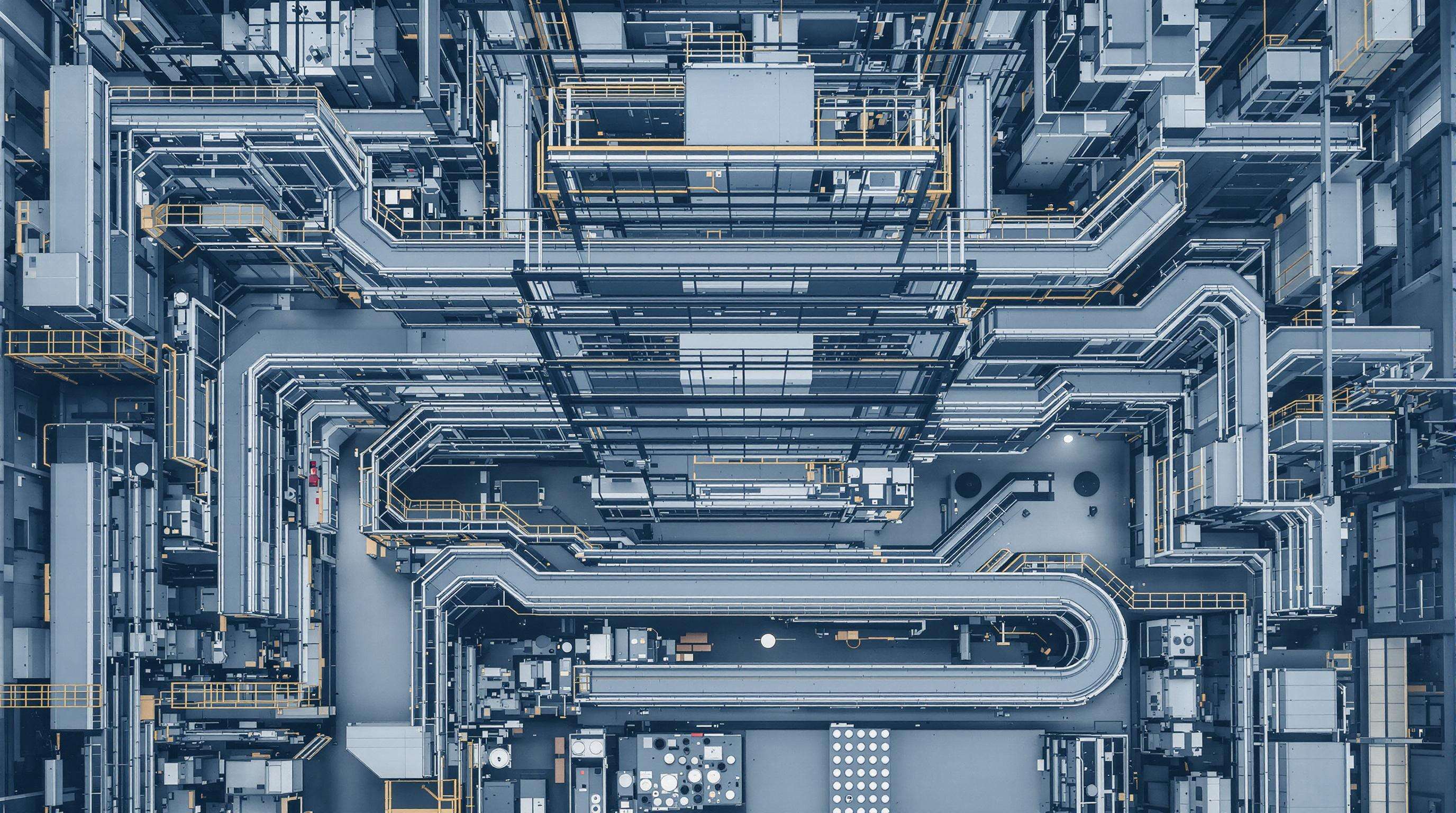

Жүктөө системасы Кеңдик жана тизме чектөөлөрү

Кеңдиктик чектөөлөргө ылайык келтирилген материалдарды ташоо системаларын оптимизациялоо үчүн стратегиялык кеңдиктик пландоо маанилүү. Негизги кыйынчылыктарга вертикаль кеңдик чектөөлөрү, туурасыз формалар жана өзгөрүп турган иш процесстеринин талаптары кирет.

Транспортердик дизайнда кеңдикти пайдаланууну максималдаштыруу

Модерн транспортер тизмелери кеңдик чектөөлөрүнө жаал чыгуу үчүн вертикаль өсүмдүк жана бир нече деңгээлдүү конфигурацияларды колдонушат. Туура чечимдерге төмөнкүлөр кирет:

- Баскычтуу продукт агымы үчүн Z-рамкалуу транспортерлер

- Иштетүү зондору ортосундагы чөйрөлөрдү күрөңдөтүүчү чүп чачындаткычтар

- Компакттуу навигация үчүн 90° чапка айлантуучу электр ролдер системасы

Ишканалык-спецификтүү тизме чектөөлөрү менен иштөө

Эгерилген белтттердин системасы (15°-45° чейинки бурчтун көркөмдүгү) түзүлүштүн туурасыз формаларына ылайыкташат, ал эми баскычтуу тасмалар төмөнкү өтүмдүүлүктөгү вертикаль ташуу көйгүйлөрүн чечет (14 фут тавандар). 24/7 операцияларда 98% упайын сактоо үчүн керектөөчү конфигурациялар.

Колдонуучу материалдарды ташуу үчүн модулдук долбоорлор

Плагин-жана-ойно компоненттер тез өзгөртүүнү камсыз кылат:

- Тез ажыратуучу тарткыч топтор (5 мүнөттөн аз алмаштыруу убактысы)

- Телескоптоочу рейкалар менен ылайыкташтырылган аймактарды көбөйтүү

- Автоматтык теселдеүчү мобильдүү негизги блоктор

Модулдук системалар убакытты түзүүнү күндөн саатка чейин кыскартат жана тайгап кетүүнүн ар квадрат метрине 18 долларга чейин кыскартат.

Тасмалоочу системаны тандаштагы материалдык өзгөчөлүктөр

Оптималдуу тасмалоочу өнүмдүүлүк үчүн бөлүкчөлөрдү талдоо

Бөлүкчөнүн өлчөмү өнүмдүлүктү белгилейт:

- <5 мм материалдар вибрациялык тасымалдағыштарда 15-20% жогорку өткөрүмдүүлүккө ээ болот

-

10 мм туурасыз бөлүкчөлөргө тизмектүү механизмдер керек

Чын убакытта чачылаткан сенсорлор дарыларды айыруу процесстерин 40% кысқартат

Сынбошу же курч заттарды колдонуу куралдарын колдонуу

Сынбош бөлүктөргө керек:

- ±0.1 м/с ичинен ылдамдыкты башкаруу

- 2 G-күчтөн төмөнкү таасир күчү

Курч заттар үчүн керек:

- Догду күрөтсүз болоттор менен эркин жалдыздалган нержел ташыгычтар (98% затты камтыйт)

- Антистатикалык белттар (10^9 омдон төмөнкү беттин каршылыгы)

Материал түрү боюнча өткөрүмдү оптималдаштыруу

| Материалдын касиети | Тасмалы транспортер түрү | Өткөрүм диапазону | Энергиянын натыйжалуулугу |

|---|---|---|---|

| Эркин агып чыгып турган тозу | Пневматика | 5-50 тонна/саат | 8-12 кВт·с/тонна |

| Бириккен гранулалар | Винт | 2-20 тонна/саат | 15-22 кВт·с/тонна |

| Ашыгын таштаган чоңдуктар | Кур | 20-500 тонна/саат | 3-7 кВт·с/тонна |

| Жогорку температурадагы шлактар | Эпрон | 10-150 тонна/саат | 18-30 кВт·с/тонна |

Түрткүлөр үчүн тамак-аш стандартындагы колдонуу 99,7% арым пайдаланууну талап кылат.

Материалдарды ташуу системалары үчүн энергия эффективдүүлүгүн жакшыртуу

Конвейерлер өнөр жай энергия колдонуунун 15-30% ээлейт. Модернизацияланган жаңылоо өнүмдүүлүктүн ырааттуулугун жана уламжарлыкты сактоону камсыз кылат.

Электр энергиясын чыгашты азайтуу үчүн акылдуу автоматтандыруу

Өзгөрмө жыштыктык жетектер (VFD) төмөн суроо учурунда энергиянын колдонуусун 40% кыскартат. IoT менен бүтүрүлгөн жүк сенсорлору чыгымды насыя убакта тактоого мүмкүнчүлүк берет, машиналык окуу тарыхый шаблондорго ылайык орнотууларды оптимизациялайт.

Материалдарды иштетүүдө тургундуу долбоордош принциптер

Энергияны кайра иштетүү системасы токтоп турган учурдагы ысып кетүүнү күчкө айландырат. Жабык системалуу суутуу жана биополимер тарткычтар циклдун жалпы чыгымдарын 18-27% төмөндөтөт жана жылына чизиктүү футка чакан 0,08-0,12 доллар чыгымды төмөндөтөт.

Склад системаларын интеграциялоо стратегиялары

Транспортердин башкаруу системасынын ылайыктуулугун текшерүү

Стандартташкан API негиздемелери интеграциялык каталарды 40% көп азайтат, ал эми жеке системалар жүктүн симуляциясы менен пик өткөрүмдүктүн убагында синхрондоону текшерет.

Эски материал иштетүү инфраструктурасын модернизациялоо

Фазалуу жаңылоо толук кайра курууга салыштырмалуу ROI (кайтарым) 25-30% тез алат. Модулдук компоненттер энергия эффективдүү приводдорду алмаштырууга мүмкүнчүлүк берет, бирок системаны толук токтотпойт.

Материал ташуу системалары үчүн коопсуздук жана техникалык кызмат көрсөтүү протоколдору

Транспортерлөр үчүн алдын ала техникалык кызмат көрсөтүү талаптары

Негизги протоколдор:

- Күнүгө бир жолу шарттарды текшерүү

- Жылдын төрттүгүндө машина майлаштыруу

- Жыл сайын лазер коллимациясын текшерүү

Цифрдык журналдар кагаз системага караганда 57% комплаенсты жакшылатат.

Транспортер жылдамдыгынын иштөө коопсуздугуна таасири

| Жылдамдыкты көбөйтүү | Коопсуздук төөндүрүүчү көбөйткүч |

|---|---|

| 10% | 1.5– |

| 25% | 3.2– |

| 50% | 6.8– |

ЖИ тарабынан башкарылуучу ылдамдыкты түзөтүү жол кызматындагы окуялардын санын 42% кыскартат. OSHA жогорку өтүмдүлүктөгү сызыктар үчүн эле коопсуздук буферин сактоону сунуш кылат.

Материал ташуу системасына кирешенин TCO талдоосу

ROI менен өнүмдүүлүктү арттыру чыгымдарын тең салуу

Жогорку өнүмдүү конвейерлердин артыкчылыктары:

- энергияны колдонуу 18-27% төмөн

- күтүм чыгымдары 22% төмөн

- прогностикалык күтүм аркылуу ROI 40% тез

Типтүү TCO түзүлүшү:

- 35-45% - жабдуу/оңдоо

- 30-40% - энергия/күтүм

- 15-25% түшүп калуу зыяндары

Тасмалагычтарды долойткондо заманбап чыгымдарды кемитүү тенденциялары

Негизги инновациялар:

- Модулдуу тартуучу тизмектүү тасмалагычтар (60% арзан кайра жабдыктоо чыгымдары)

- Энергияны кайра иштетүүчү вертикаль көтөргүчтөр (15-20% электр энергиясын кайра пайдалануу)

- 3D-басылган тозуучу бөлүктөр (3 эсе узун кызмат көрсөтүү мүмкүнчүлүгү)

Бул жетишкендиктер жалпы чыгымдарды 19-28% кемитет, бирок өткөрүлүүчү көлөм сакталат. Акылдуу тармактар материалдарды ташуу боюнча окуяларды 31% кемитет.

ККБ

Материалдарды тасмалоочу системаларды долойткондо кандай негизги кыйынчылыктар бар?

Негизги кыйынчылыктар вертикаль кеңештик чектөөлөр менен, башкаларга тууралуу жайлоо шарттары жана өзгөрүп турган иш процесстерине ылайыкташтыруу болуп саналат.

Заманбап тасмалагычтардын жайгаштырылышы кеңештик маселелерин кантип чечет?

Модернизделген тасымалдау тизмектеринин пландоосу вертикалдуу катмардоо жана бир нече деңгээлдүү конфигурацияларды колдонот, мисалы, Z-рамкалуу тасымалдагычтар, чагылдыруучу өткөрүү түтүктөрү жана 90° бүркөтүүчү күчтөлгөн роликтер менен жабдылган системалар кеңири пайдаланууну максималдаш үчүн.

Коопсуздукту камсыз кылуу үчүн өзгөчө тасымалдагычтар керектелген материалдар кандай?

Бузулмалуу жана курч эрежелүү материалдар өзгөчө тасымалдау шарттарын талап кылат. Бузулмалуу материалдар так айлана тездиги менен чектөө жана таасир күчүн чектөөнү талап кырат, ал эми курч эрежелүү материалдар үчүн үзгүлтүксүз даярдалган тегерек болоттон жасалган тасымалдагычтар жана антистатикалык белттер керек.

Материал тасымалдоо системаларында энергия эффективдүүлүгүн кантип арттыру мүмкүн?

Энергия эффективдүүлүгүн арттыру үчүн тийиштүү автоматташтырууларды, мисалы, Өзгөрмө Жыштык Драйверлери (VFD), IoT менен байланышкан жүк сенсорлору, энергия кайтаруу системалары жана туюк циркулдуу суу менен түтүктөлгөн жана биополимер белттер сымал туруктуу дизайн элементтерин колдонуу мүмкүн.

Тасымалдау тизмектерин техникалык күтүү боюнча жалпы талаптар кандай?

Күн сайынкы көрүнүп текшерүү, ай сайынкы майлаштыруу, жыл сайын лазер коллимациясын текшерүү сыяктуу жалпы техникалык кызмат көрсөтүү протоколдору талаптарга ылайыктуулукту жана иштөө эффективдүүлүгүн арттырышы мүмкүн.

Көрсөтмө

- Жүктөө системасы Кеңдик жана тизме чектөөлөрү

- Тасмалоочу системаны тандаштагы материалдык өзгөчөлүктөр

- Материалдарды ташуу системалары үчүн энергия эффективдүүлүгүн жакшыртуу

- Склад системаларын интеграциялоо стратегиялары

- Материал ташуу системалары үчүн коопсуздук жана техникалык кызмат көрсөтүү протоколдору

- Материал ташуу системасына кирешенин TCO талдоосу

-

ККБ

- Материалдарды тасмалоочу системаларды долойткондо кандай негизги кыйынчылыктар бар?

- Заманбап тасмалагычтардын жайгаштырылышы кеңештик маселелерин кантип чечет?

- Коопсуздукту камсыз кылуу үчүн өзгөчө тасымалдагычтар керектелген материалдар кандай?

- Материал тасымалдоо системаларында энергия эффективдүүлүгүн кантип арттыру мүмкүн?

- Тасымалдау тизмектерин техникалык күтүү боюнча жалпы талаптар кандай?