Principia Principalia Quae Subiacent Machina Scillae Oscillantis Operatio

Mechanica Vibrationis Secernendi Materiales

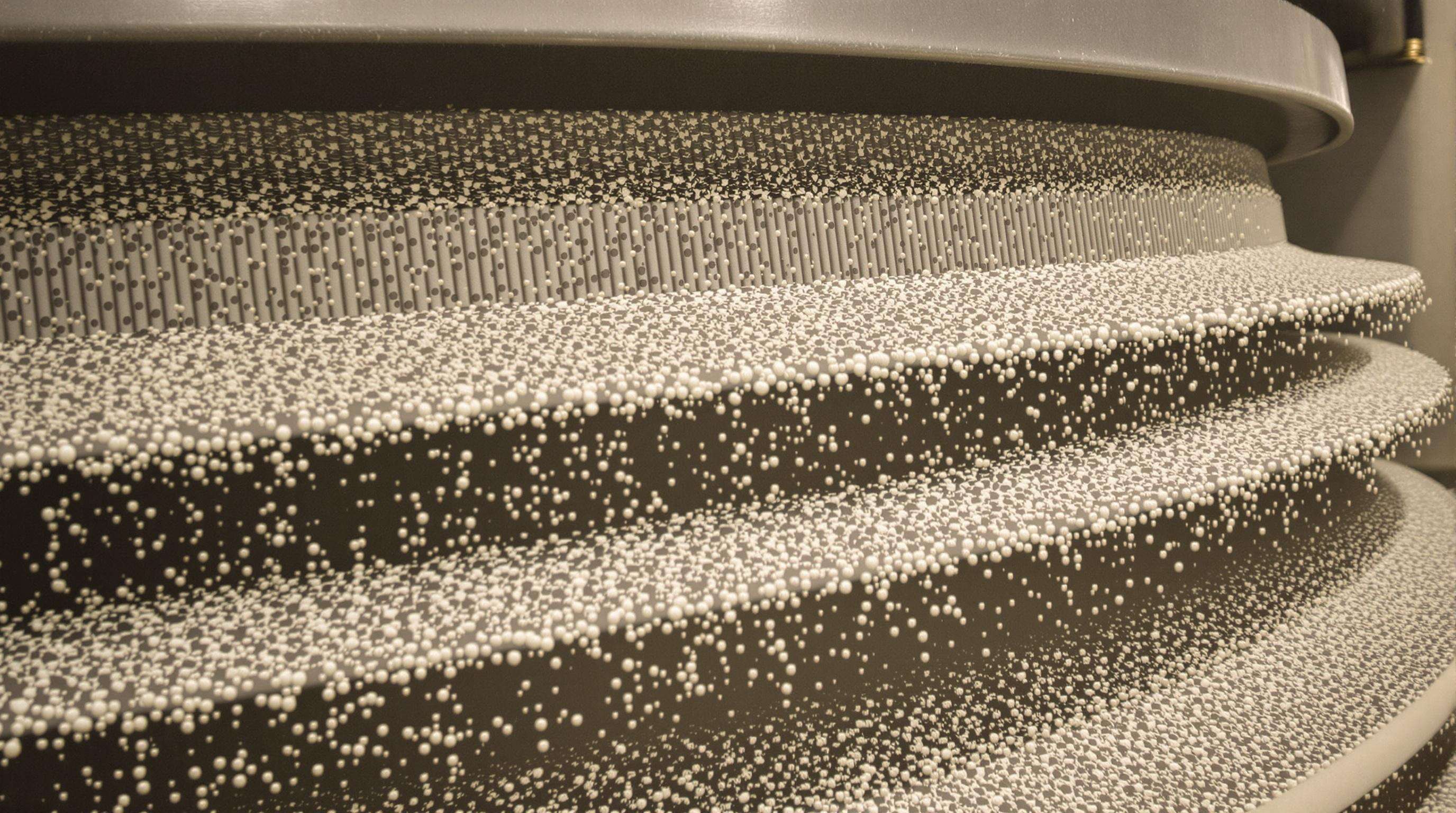

Tela vibrante in mobilitate creant actionem fluidam per gravitatis motum et parvam accelerationem, generantes actionem per gyratoriam motione parvi RPM. Hac motione ellittica series minutorum ictuum fit, incluse STEP, partem super superficiem obliquam removetur, ut partem accelerent et densiorem quae non facile mergitur colligatur, ut finae particulae diutissime in crivis manent. Optima emendatio temporis commorandi partium finarum assequi potest 40-65% respectu crivi lineari. Mollis gliscentis actio minimat necessitatem mallei purgandi, usque ad 70% in materialibus tenacibus ut lapide calcario humido—necessaria ad dedustationem et separationem materialium adhaesivorum.

Calculatio Efficientiae Tamisationis in Ratione Processus

Ingeniarii processuum emendationem perficiunt per metrices efficientiae mensurabiles:

| Facter Calculi | Formula | Finis Constat Norma Industriae |

|---|---|---|

| Ratio Recuperationis Minoris Magnitudinis | (Actus Transitus · Theoricus) ÷ 100 | 90-96% |

| Contaminatio Prope Magnitudinem | Particulae nimis magnae in fractione effluente | ≤ 5% |

| Usus strati cribri | Area utilis · Area nominis | ≥ 85% |

Contra ponere velocitates distributionis cum parametris vibrationis (2.5-5.0G intervallum) efficit optimam stratificationem sine effluvio cito facto nec rursus inhaerendo.

Comportamentum materiae in processu cribrandi mechanicis

Particulae percurrunt distinctas phases stratificationis:

- Strati – Fractio crassior sursum fertur dum tenuia per spatia interstitia descendent

- Secernere – Vibrationes ellipticae turbidum motum inducunt, separationem ex magnitudine accelerantes.

- Exitus – Particulae prope-mesh rite rotant extra vias electricas, minuendo obstruccionem.

Spira progressio collisionum partium contra parietes damnum minuit 35%, praesertim utile pro lapidibus argillosis ubi cernae vulgares laborant.

Partes Principales Quae Processum Cernendi Efficiunt

Structura Deck Cernae et Configuratio Mesh

Mensura aperturae et ratio spatii aperti separationis praecisionem regunt. Polyurethanea cernae metallinis sunt aeterniores pro materialibus asperis, aucta area filtrationis usque ad 35%.

Motor Eccentricus et Dynamica Contrapesorum

Contrapesa regolabiles amplitudinem (2-10mm) modulant ad materiae densitates accommodandas, dum tamen vim 4-6G conservant. Haec systemata usum energiae minuunt 18% versus motus vibrantes vulgares.

Designus Extremitatis Disiicientis pro Output Graduato

Canalia scalata cum angulis 5-15° puritatem materialis 99.7% in operationibus unius transitus conservant. Limites rationabiles fluxum regulant ad capacitatem convenientem convayorum subsequentium.

Explicatio Gradatim Operationis Cernae Oscillatoriae

Initium cursus et controlla securitatis

- Controlla tuta et separationem electricam

- Testis vibrationis basilineae interdum

- Confirma funtionem stoppae emergentiae secundum normas OSHA

Optimizatio schematis pabuli materiae

- Serva texiturae 65-75% per canales regolabiles

- Regula inductum ad 2-5 tonnas/hora pro pulveribus tenuibus

Processus separationis multiphase

Rotatio frequenciae infimae (8-12 rpm) traiectorias spirales creat, efficiens 22% altiorem quam systemata linearia pro materialibus cohaerentibus

Observatio continua per portillas

- Controlla pattern migrationis materiae omni 4-5 cyclis.

- Usa sensorum infrarubrorum ad temperaturam rotulorum explorandam.

Claustrum Regulatum et Residuorum Administratio

Post motum vibrationem residualem 95%+ materiae purgat. Pennae veloci liberandi sinit raschionem mechanicam reliquiae adhaesivae.

Optimizatio Perforationum Oscillationis in Productione

Amplitudinis Regulatio pro Diversis Magnitudinibus Materiae

- Particulae crassae : 8-12mm amplitudo obstruccionem vitat.

- Pulveres subtilis : 4-7mm perdimissionem aeriam minuit.

Gestio Rationis Prohibendi Superfluitatem

Sensus oneris lentescunt oblatorum, cum congestio plus 20% basis excedit. Oblatio centralis vacua peripheria minuit 60%.

Analysis Usum Plagae Pro Tempore Substituendi

| Locus Usum | Indicatio Molestiae | Actio |

|---|---|---|

| Exodus Finis | Imbrium inaequalitas | Mox substitue |

| Oblatio Finis | Laesio ictus | Pone substitutionem |

Protocolla conservationis ad efficientiam diuturnam examinandi

Schema quotidiana unguendi

Unguentum crassum in articulis cardinis praeventionem adhibet ad 38% defectuum thermalium.

Substitutio bi-mensis cunei

Cunei eccentrici praedictabiliter deteriunt in 6-8 hebdomadibus; axes inter insertionis tempus aptare.

Annuale examen firmitatis fabricii

Examina pro tortuositate (±3mm spatium) et rimis fatigalis per calibros ultrasonicos.

Solutiones problematum frequentium in machina vagantis examinandi

Incerti motus vibrationum

75% proveniunt ex neglegentia ferularum. Adhibe allineationem laser et thermographiam infrarubram ad diagnoscendum.

Obnubilatio laminae in materialibus viscidis

Reticula polyurethanica obturationem minuunt 40%. Eruptiones aeris ad altam pressionem fluxum servant.

Motorum Obcalescentia

Sensoria thermalia clausuram debent incitare ad 71°C (160°F). Verifica ventilationem et stabilitatem voltionis.

FAQ

Quae est praecipua ratio utendi laminis vibratoriae oscillantium?

Laminae oscillantes vibratoriae separationem partium emendent cum cura minima, praesertim pro materialibus viscidis.

Quomodo obnubilatio laminae praeventari potest in materialibus viscidis?

Reticulis polyurethanicis et eruptionibus aeris ad altam pressionem adhibitis, difficultates obnubilationis laminae notabiliter minui possunt.

Quae examina de salute sunt antequam machinae laminae oscillantis incipiuntur?

Munera tutela verificare, testem vibrationis fundamentalem agere, et munera stoppae emergentiae confirmare sunt praecipua subsidia tutelae.

Index Rerum

- Principia Principalia Quae Subiacent Machina Scillae Oscillantis Operatio

- Partes Principales Quae Processum Cernendi Efficiunt

- Explicatio Gradatim Operationis Cernae Oscillatoriae

- Optimizatio Perforationum Oscillationis in Productione

- Protocolla conservationis ad efficientiam diuturnam examinandi

- Solutiones problematum frequentium in machina vagantis examinandi

- FAQ